Huntingdon Fusion

Showing 1–15 of 34 results

-

High Purity Equipment

HFT Dew Point (Moisture) Sensor

Huntingdon Fusion Techniques Dew Point Sensor *For use in conjuction with HFT PurgeEye Oxygen Monitors that use PurgeNet softwareMoisture Sensor that can read PPM moisture simultaneously with PPM oxygen.Data is displayed on the OLED screen of the Weld PurgeMonitor® in split format so both oxygen in PPM and moisture content are shown.

SKU: n/a -

High Purity Equipment

Accu-Freeze™ Automatic Controlled Liquid Nitrogen Pipe Freezing Systems

Freeze it and make your Pipe Repair Easy!

Accu-Freeze™, the controlled liquid nitrogen (LN2) pipe freezing system is a method to freeze stationary liquids in a selected section of a pipe or tubing. It is the World’s only patented, digitally controlled pipe freezing system thus allowing you to accurately and safety create an ice plug.

By controlling the surface temperature of the pipe, Accu-Freeze™ can safely and accurately form an in-line ice plug, capable of withstanding 138 bar (2000 Psi) in pipes up to 12″ (300 mm diameter).

SKU: n/a -

High Purity Equipment

Argweld® Argon Gas Feed Hose Assemblies with Optional Fittings

Use High Quality Argon Feed Hose Assemblies and Fittings

Argon Feed Hose is available off the shelf complete with end fittings in a standard range of lengths, 30m, 25m, 20m, 15m, 10m and 5m. Each assembly is of a high standard and comes complete with an argon regulator fitting one end and a 12 mm to 12 mm quick connect fitting at the other end. There are alternative fittings available in the range including hose tails, tailpieces and a variety of quick disconnect options.

SKU: n/a -

High Purity Equipment

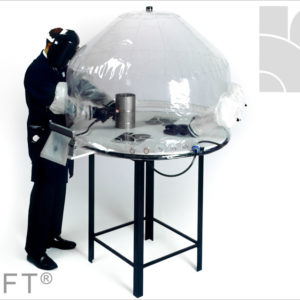

Argweld® Flexible Weld Purging Enclosures®

Ergonomic, Flexible and Clear!

The Argweld® range of Flexible Welding Enclosures® has been designed for applications where a rigid chamber may not be economically viable or where space may be at a premium, they are low cost, suitable for welding titanium, zirconium, other reactive metals and for WAAM Additive Manufacturing.

Typical applications include the occasional and production welding of titanium and nickel alloy components for the aerospace, medical and racing car industries and for the welding of stainless steel components to eliminate the expensive cleaning of discolouration.

Apart from the standard models, special enclosures are designed and manufactured to suit all applications. Experience is available of nuclear and chemical industry applications for the handling of a wide range of products and materials, as well as in the pipeline industry with clam shell models to fit on and off pipes.

SKU: n/a -

High Purity Equipment

Argweld® HotPurge® Heat Resistant Inflatable Pipe Weld Purging Systems

Purge your Heat-Treated Pipework Confidently!

Argweld® HotPurge® Inflatable Pipe Weld Purge Systems for Heat-Treated Pipework have been developed so that pre-heating, welding and post weld heat treatment can be carried out with the purge system in place. Using the latest IntaCal® and PurgeGate® technology to inflate the dams, purge the weld zone with the guarantee that the purge dams cannot burst through over pressurisation. In addition RootGlo® can be used for accurate positioning of the system precisely under the joint.

SKU: n/a -

High Purity Equipment

Argweld® Inflatable Single Ended Weld Purge Dams

Single Ended for Closing Welds!

Argweld® Inflatable Weld Pipe Purging Dams are a low-cost alternative to plastic foam or cardboard dams that are still very frequently hand made at great expense by welders on site.

Inflatable Dams are manufactured from advanced low outgassing rate materials and are ideal for applications where Argweld® Tandem Pipe Purging Systems or the older style Purge Bladder Systems are less suitable.

These simple to use, easy to insert Argweld® Inflatable Weld Purge Dams can be purchased for any diameter within their manufacturing range and can be used in connection with other styles or sizes of dams elsewhere within the piping system.

SKU: n/a -

High Purity Equipment

Argweld® Mark V Weld Purge Monitor®

Update Mark V to PurgEye® 100 IP65 Weld Purge Monitor®

Argweld® Mark V Weld Purge Monitor® Out of Date and Updated

Argweld® PurgEye® 100 IP65 NEW Features:

• Push button ‘Auto Calibration’ feature

• Low Battery Indicator

• Low Sensor Indicator

• Enlarged Screen and Larger Digits

• Tripod Mount

• Increased Sensor Reading Range

• Wrist and Neck Carry Strap

• Protective Rubber Housing (optional accessory)

• Automatic Sleep Mode when not in use

• Leak-Tight Stainless Steel Probe and Gas Hose Asssembly

• Quick connect/disconnect Fittings for gas purge tubingSKU: n/a -

High Purity Equipment

Argweld® PurgElite® Purge Bladders and Dams

Purge your Tubes and Pipes the ‘Elite’ way

Purging Systems, Purge Bladders and Purge Dams, using real scientific purge bladder breakthrough technology, Argweld® PurgElite® Inflatable Tube and Pipe Weld Purging Systems introduces to the market place for the first time a ‘New’ 1 inch (25 mm) System for small diameter tubes and pipes. Another great innovation to help tube and pipe welders save time, money, gas and achieve better welds. The volume to purge is kept small, resulting in savings in both time and cost of inert gas used. Purge bladders and dams suitable for high quality pristine tube and pipe weld purging, 1 to 24″ (25 to 600 mm) diameters. For full technical information, use the tabs above.

SKU: n/a -

High Purity Equipment

Argweld® PurgEye® 100 Hand Held IP65 Weld Purge Monitor®

Argweld® PurgEye® 100 IP65 has additional features that place this Weld Purge Monitor® way ahead in the field of Weld Purge Monitoring.

Huntingdon Fusion Techniques HFT® is the first company to have developed a Weld Purge Monitor®. The Company has continued to innovate year by year bringing to the market place a complete family range of weld purge monitoring instruments for other materials including duplex, nickel and cobalt steels, titanium, zirconium and other reactive alloys.

Joining the other existing models in the range, the Argweld® PurgEye® 100 IP65 makes Huntingdon Fusion Techniques HFT® the only Company to have a complete ‘family’ of Weld Purge Monitors® s for all applications and to suit every budget.

This exciting new PurgEye® 100 IP65 Weld Purge Monitor® replaces our out of date and obsolete Argweld® Mark V (MKV) Weld Purge Monitor® which used old technology in comparison with this latest revoluntary model.

SKU: n/a -

High Purity Equipment

Argweld® PurgEye® 1000 Remote Weld Purge Monitor®

Keep a distant ‘Eye’ on your Purge… up to 1 km away!

The World’s ‘first and only‘ remote Weld Purge Monitor®, measuring accurately down to 10 ppm. With an internal mechanical pump, all powered by the data cable from the display unit.

When welding joints in long tube line or pipeline sections, it is not normally practical to measure the purge gas exhaust close to the weld.

Measuring purge gas exiting in the joint gap is also unsatisfactory because of the heat generated in that area, the oxygen being drawn in from outside and other variable factors.

HFT® has developed an answer to this difficulty, namely a remote sensing head that can be fitted onto the purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the monitor up to 1 km away.

In this way, the operator can be certain that the weld purge reading is correct and that the joint will not be adversely affected by oxidation.

PurgEye® a Family Series of Weld Purge Monitors®.

SKU: n/a -

High Purity Equipment

Argweld® PurgEye® 1500 Site IP68 Weld Purge Monitor®

Measuring Down to 1 ppm!

The latest addition to the Family Range of PurgEye ® Weld Purge Monitors ® is the PurgEye ® 1-500 Site, portable, robust and specifically designed for site conditions.

The PurgEye ® Site reads oxygen levels from 1000 ppm, right down to 1 ppm (accurate to 10 ppm) with a long life sensor and new, ultra sharp OLED screen.

The PurgEye ® Site is mounted in a conveniently sized outer case, which seals it to IP68 standard when the lid is closed.

The Family Range of Weld Purge Monitors® have become the standard Weld Purge instruments of today, recognised and used by companies who need to produce quality welds, where an Oxygen Analzyer is not sufficient for weld purging.

PurgEye ® is a Family Series of Weld Purge Monitors ®.

SKU: n/a -

High Purity Equipment

HFT PurgEye® 200 IP65 Rechargeable Weld Purge Monitor®

Accurately measuring down to 10 ppm

Now with an OLED (organic light emitting diode) display, the PurgEye ® 200 Weld Purge Monitor ® gives sharper, brighter and clearer readings for viewing at longer distances than before. The OLED display is mainly symbol based, which means the menus are easily understandable regardless of which languages the user speaks.

Main Features:

• Internal electro-mechanical pump with 1 l/m flow rate.• USB lead included to control PurgeLog™ software.

• IP65 rated.

• Long life, faster response sensor.

• Internal rechargeable battery or mains power operated.

• Battery life up to 10 hours.

• Hand held easy to use instrument.

• Warning alarm levels between 1 and 999 ppm.

• Flow detection for accurate reading of gas samples.

• Outstanding protection against HF interference.

• Large character OLED screen for easy reading.

• Power on / off with standby button for sensor warm up.

• Can be charged by plugging directly into mains power with charging lead or optional charging dock.

SKU: n/a -

High Purity Equipment

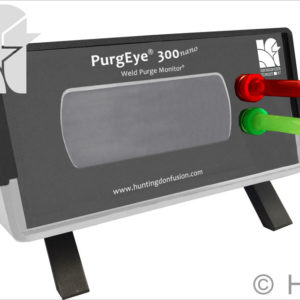

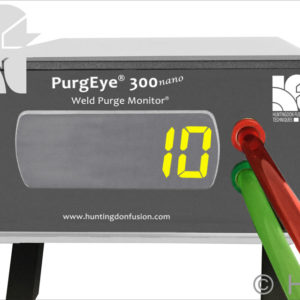

Argweld® PurgEye® 300 Nano Weld Purge Monitor®

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.

SKU: n/a -

High Purity Equipment

Argweld® PurgEye® 300 Plus Small and Lightweight

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.

SKU: n/a

-

High Purity Equipment

HFT Dew Point (Moisture) Sensor

Huntingdon Fusion Techniques Dew Point Sensor *For use in conjuction with HFT PurgeEye Oxygen Monitors that use PurgeNet softwareMoisture Sensor that can read PPM moisture simultaneously with PPM oxygen.Data is displayed on the OLED screen of the Weld PurgeMonitor® in split format so both oxygen in PPM and moisture content are shown.

-

High Purity Equipment

Accu-Freeze™ Automatic Controlled Liquid Nitrogen Pipe Freezing Systems

Freeze it and make your Pipe Repair Easy!

Accu-Freeze™, the controlled liquid nitrogen (LN2) pipe freezing system is a method to freeze stationary liquids in a selected section of a pipe or tubing. It is the World’s only patented, digitally controlled pipe freezing system thus allowing you to accurately and safety create an ice plug.

By controlling the surface temperature of the pipe, Accu-Freeze™ can safely and accurately form an in-line ice plug, capable of withstanding 138 bar (2000 Psi) in pipes up to 12″ (300 mm diameter).

-

High Purity Equipment

Argweld® Argon Gas Feed Hose Assemblies with Optional Fittings

Use High Quality Argon Feed Hose Assemblies and Fittings

Argon Feed Hose is available off the shelf complete with end fittings in a standard range of lengths, 30m, 25m, 20m, 15m, 10m and 5m. Each assembly is of a high standard and comes complete with an argon regulator fitting one end and a 12 mm to 12 mm quick connect fitting at the other end. There are alternative fittings available in the range including hose tails, tailpieces and a variety of quick disconnect options.

-

High Purity Equipment

Argweld® Flexible Weld Purging Enclosures®

Ergonomic, Flexible and Clear!

The Argweld® range of Flexible Welding Enclosures® has been designed for applications where a rigid chamber may not be economically viable or where space may be at a premium, they are low cost, suitable for welding titanium, zirconium, other reactive metals and for WAAM Additive Manufacturing.

Typical applications include the occasional and production welding of titanium and nickel alloy components for the aerospace, medical and racing car industries and for the welding of stainless steel components to eliminate the expensive cleaning of discolouration.

Apart from the standard models, special enclosures are designed and manufactured to suit all applications. Experience is available of nuclear and chemical industry applications for the handling of a wide range of products and materials, as well as in the pipeline industry with clam shell models to fit on and off pipes.

-

High Purity Equipment

Argweld® HotPurge® Heat Resistant Inflatable Pipe Weld Purging Systems

Purge your Heat-Treated Pipework Confidently!

Argweld® HotPurge® Inflatable Pipe Weld Purge Systems for Heat-Treated Pipework have been developed so that pre-heating, welding and post weld heat treatment can be carried out with the purge system in place. Using the latest IntaCal® and PurgeGate® technology to inflate the dams, purge the weld zone with the guarantee that the purge dams cannot burst through over pressurisation. In addition RootGlo® can be used for accurate positioning of the system precisely under the joint.

-

High Purity Equipment

Argweld® Inflatable Single Ended Weld Purge Dams

Single Ended for Closing Welds!

Argweld® Inflatable Weld Pipe Purging Dams are a low-cost alternative to plastic foam or cardboard dams that are still very frequently hand made at great expense by welders on site.

Inflatable Dams are manufactured from advanced low outgassing rate materials and are ideal for applications where Argweld® Tandem Pipe Purging Systems or the older style Purge Bladder Systems are less suitable.

These simple to use, easy to insert Argweld® Inflatable Weld Purge Dams can be purchased for any diameter within their manufacturing range and can be used in connection with other styles or sizes of dams elsewhere within the piping system.

-

High Purity Equipment

Argweld® Mark V Weld Purge Monitor®

Update Mark V to PurgEye® 100 IP65 Weld Purge Monitor®

Argweld® Mark V Weld Purge Monitor® Out of Date and Updated

Argweld® PurgEye® 100 IP65 NEW Features:

• Push button ‘Auto Calibration’ feature

• Low Battery Indicator

• Low Sensor Indicator

• Enlarged Screen and Larger Digits

• Tripod Mount

• Increased Sensor Reading Range

• Wrist and Neck Carry Strap

• Protective Rubber Housing (optional accessory)

• Automatic Sleep Mode when not in use

• Leak-Tight Stainless Steel Probe and Gas Hose Asssembly

• Quick connect/disconnect Fittings for gas purge tubing -

High Purity Equipment

Argweld® PurgElite® Purge Bladders and Dams

Purge your Tubes and Pipes the ‘Elite’ way

Purging Systems, Purge Bladders and Purge Dams, using real scientific purge bladder breakthrough technology, Argweld® PurgElite® Inflatable Tube and Pipe Weld Purging Systems introduces to the market place for the first time a ‘New’ 1 inch (25 mm) System for small diameter tubes and pipes. Another great innovation to help tube and pipe welders save time, money, gas and achieve better welds. The volume to purge is kept small, resulting in savings in both time and cost of inert gas used. Purge bladders and dams suitable for high quality pristine tube and pipe weld purging, 1 to 24″ (25 to 600 mm) diameters. For full technical information, use the tabs above.

-

High Purity Equipment

Argweld® PurgEye® 100 Hand Held IP65 Weld Purge Monitor®

Argweld® PurgEye® 100 IP65 has additional features that place this Weld Purge Monitor® way ahead in the field of Weld Purge Monitoring.

Huntingdon Fusion Techniques HFT® is the first company to have developed a Weld Purge Monitor®. The Company has continued to innovate year by year bringing to the market place a complete family range of weld purge monitoring instruments for other materials including duplex, nickel and cobalt steels, titanium, zirconium and other reactive alloys.

Joining the other existing models in the range, the Argweld® PurgEye® 100 IP65 makes Huntingdon Fusion Techniques HFT® the only Company to have a complete ‘family’ of Weld Purge Monitors® s for all applications and to suit every budget.

This exciting new PurgEye® 100 IP65 Weld Purge Monitor® replaces our out of date and obsolete Argweld® Mark V (MKV) Weld Purge Monitor® which used old technology in comparison with this latest revoluntary model.

-

High Purity Equipment

Argweld® PurgEye® 1000 Remote Weld Purge Monitor®

Keep a distant ‘Eye’ on your Purge… up to 1 km away!

The World’s ‘first and only‘ remote Weld Purge Monitor®, measuring accurately down to 10 ppm. With an internal mechanical pump, all powered by the data cable from the display unit.

When welding joints in long tube line or pipeline sections, it is not normally practical to measure the purge gas exhaust close to the weld.

Measuring purge gas exiting in the joint gap is also unsatisfactory because of the heat generated in that area, the oxygen being drawn in from outside and other variable factors.

HFT® has developed an answer to this difficulty, namely a remote sensing head that can be fitted onto the purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the monitor up to 1 km away.

In this way, the operator can be certain that the weld purge reading is correct and that the joint will not be adversely affected by oxidation.

PurgEye® a Family Series of Weld Purge Monitors®.

-

High Purity Equipment

Argweld® PurgEye® 1500 Site IP68 Weld Purge Monitor®

Measuring Down to 1 ppm!

The latest addition to the Family Range of PurgEye ® Weld Purge Monitors ® is the PurgEye ® 1-500 Site, portable, robust and specifically designed for site conditions.

The PurgEye ® Site reads oxygen levels from 1000 ppm, right down to 1 ppm (accurate to 10 ppm) with a long life sensor and new, ultra sharp OLED screen.

The PurgEye ® Site is mounted in a conveniently sized outer case, which seals it to IP68 standard when the lid is closed.

The Family Range of Weld Purge Monitors® have become the standard Weld Purge instruments of today, recognised and used by companies who need to produce quality welds, where an Oxygen Analzyer is not sufficient for weld purging.

PurgEye ® is a Family Series of Weld Purge Monitors ®.

-

High Purity Equipment

HFT PurgEye® 200 IP65 Rechargeable Weld Purge Monitor®

Accurately measuring down to 10 ppm

Now with an OLED (organic light emitting diode) display, the PurgEye ® 200 Weld Purge Monitor ® gives sharper, brighter and clearer readings for viewing at longer distances than before. The OLED display is mainly symbol based, which means the menus are easily understandable regardless of which languages the user speaks.

Main Features:

• Internal electro-mechanical pump with 1 l/m flow rate.• USB lead included to control PurgeLog™ software.

• IP65 rated.

• Long life, faster response sensor.

• Internal rechargeable battery or mains power operated.

• Battery life up to 10 hours.

• Hand held easy to use instrument.

• Warning alarm levels between 1 and 999 ppm.

• Flow detection for accurate reading of gas samples.

• Outstanding protection against HF interference.

• Large character OLED screen for easy reading.

• Power on / off with standby button for sensor warm up.

• Can be charged by plugging directly into mains power with charging lead or optional charging dock.

-

High Purity Equipment

Argweld® PurgEye® 300 Nano Weld Purge Monitor®

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.

-

High Purity Equipment

Argweld® PurgEye® 300 Plus Small and Lightweight

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.

-

High Purity Equipment

HFT Dew Point (Moisture) Sensor

Huntingdon Fusion Techniques Dew Point Sensor *For use in conjuction with HFT PurgeEye Oxygen Monitors that use PurgeNet softwareMoisture Sensor that can read PPM moisture simultaneously with PPM oxygen.Data is displayed on the OLED screen of the Weld PurgeMonitor® in split format so both oxygen in PPM and moisture content are shown.

-

High Purity Equipment

Accu-Freeze™ Automatic Controlled Liquid Nitrogen Pipe Freezing Systems

Freeze it and make your Pipe Repair Easy!

Accu-Freeze™, the controlled liquid nitrogen (LN2) pipe freezing system is a method to freeze stationary liquids in a selected section of a pipe or tubing. It is the World’s only patented, digitally controlled pipe freezing system thus allowing you to accurately and safety create an ice plug.

By controlling the surface temperature of the pipe, Accu-Freeze™ can safely and accurately form an in-line ice plug, capable of withstanding 138 bar (2000 Psi) in pipes up to 12″ (300 mm diameter).

-

High Purity Equipment

Argweld® Argon Gas Feed Hose Assemblies with Optional Fittings

Use High Quality Argon Feed Hose Assemblies and Fittings

Argon Feed Hose is available off the shelf complete with end fittings in a standard range of lengths, 30m, 25m, 20m, 15m, 10m and 5m. Each assembly is of a high standard and comes complete with an argon regulator fitting one end and a 12 mm to 12 mm quick connect fitting at the other end. There are alternative fittings available in the range including hose tails, tailpieces and a variety of quick disconnect options.

-

High Purity Equipment

Argweld® Flexible Weld Purging Enclosures®

Ergonomic, Flexible and Clear!

The Argweld® range of Flexible Welding Enclosures® has been designed for applications where a rigid chamber may not be economically viable or where space may be at a premium, they are low cost, suitable for welding titanium, zirconium, other reactive metals and for WAAM Additive Manufacturing.

Typical applications include the occasional and production welding of titanium and nickel alloy components for the aerospace, medical and racing car industries and for the welding of stainless steel components to eliminate the expensive cleaning of discolouration.

Apart from the standard models, special enclosures are designed and manufactured to suit all applications. Experience is available of nuclear and chemical industry applications for the handling of a wide range of products and materials, as well as in the pipeline industry with clam shell models to fit on and off pipes.

-

High Purity Equipment

Argweld® HotPurge® Heat Resistant Inflatable Pipe Weld Purging Systems

Purge your Heat-Treated Pipework Confidently!

Argweld® HotPurge® Inflatable Pipe Weld Purge Systems for Heat-Treated Pipework have been developed so that pre-heating, welding and post weld heat treatment can be carried out with the purge system in place. Using the latest IntaCal® and PurgeGate® technology to inflate the dams, purge the weld zone with the guarantee that the purge dams cannot burst through over pressurisation. In addition RootGlo® can be used for accurate positioning of the system precisely under the joint.

-

High Purity Equipment

Argweld® Inflatable Single Ended Weld Purge Dams

Single Ended for Closing Welds!

Argweld® Inflatable Weld Pipe Purging Dams are a low-cost alternative to plastic foam or cardboard dams that are still very frequently hand made at great expense by welders on site.

Inflatable Dams are manufactured from advanced low outgassing rate materials and are ideal for applications where Argweld® Tandem Pipe Purging Systems or the older style Purge Bladder Systems are less suitable.

These simple to use, easy to insert Argweld® Inflatable Weld Purge Dams can be purchased for any diameter within their manufacturing range and can be used in connection with other styles or sizes of dams elsewhere within the piping system.

-

High Purity Equipment

Argweld® Mark V Weld Purge Monitor®

Update Mark V to PurgEye® 100 IP65 Weld Purge Monitor®

Argweld® Mark V Weld Purge Monitor® Out of Date and Updated

Argweld® PurgEye® 100 IP65 NEW Features:

• Push button ‘Auto Calibration’ feature

• Low Battery Indicator

• Low Sensor Indicator

• Enlarged Screen and Larger Digits

• Tripod Mount

• Increased Sensor Reading Range

• Wrist and Neck Carry Strap

• Protective Rubber Housing (optional accessory)

• Automatic Sleep Mode when not in use

• Leak-Tight Stainless Steel Probe and Gas Hose Asssembly

• Quick connect/disconnect Fittings for gas purge tubing -

High Purity Equipment

Argweld® PurgElite® Purge Bladders and Dams

Purge your Tubes and Pipes the ‘Elite’ way

Purging Systems, Purge Bladders and Purge Dams, using real scientific purge bladder breakthrough technology, Argweld® PurgElite® Inflatable Tube and Pipe Weld Purging Systems introduces to the market place for the first time a ‘New’ 1 inch (25 mm) System for small diameter tubes and pipes. Another great innovation to help tube and pipe welders save time, money, gas and achieve better welds. The volume to purge is kept small, resulting in savings in both time and cost of inert gas used. Purge bladders and dams suitable for high quality pristine tube and pipe weld purging, 1 to 24″ (25 to 600 mm) diameters. For full technical information, use the tabs above.

-

High Purity Equipment

Argweld® PurgEye® 100 Hand Held IP65 Weld Purge Monitor®

Argweld® PurgEye® 100 IP65 has additional features that place this Weld Purge Monitor® way ahead in the field of Weld Purge Monitoring.

Huntingdon Fusion Techniques HFT® is the first company to have developed a Weld Purge Monitor®. The Company has continued to innovate year by year bringing to the market place a complete family range of weld purge monitoring instruments for other materials including duplex, nickel and cobalt steels, titanium, zirconium and other reactive alloys.

Joining the other existing models in the range, the Argweld® PurgEye® 100 IP65 makes Huntingdon Fusion Techniques HFT® the only Company to have a complete ‘family’ of Weld Purge Monitors® s for all applications and to suit every budget.

This exciting new PurgEye® 100 IP65 Weld Purge Monitor® replaces our out of date and obsolete Argweld® Mark V (MKV) Weld Purge Monitor® which used old technology in comparison with this latest revoluntary model.

-

High Purity Equipment

Argweld® PurgEye® 1000 Remote Weld Purge Monitor®

Keep a distant ‘Eye’ on your Purge… up to 1 km away!

The World’s ‘first and only‘ remote Weld Purge Monitor®, measuring accurately down to 10 ppm. With an internal mechanical pump, all powered by the data cable from the display unit.

When welding joints in long tube line or pipeline sections, it is not normally practical to measure the purge gas exhaust close to the weld.

Measuring purge gas exiting in the joint gap is also unsatisfactory because of the heat generated in that area, the oxygen being drawn in from outside and other variable factors.

HFT® has developed an answer to this difficulty, namely a remote sensing head that can be fitted onto the purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the monitor up to 1 km away.

In this way, the operator can be certain that the weld purge reading is correct and that the joint will not be adversely affected by oxidation.

PurgEye® a Family Series of Weld Purge Monitors®.

-

High Purity Equipment

Argweld® PurgEye® 1500 Site IP68 Weld Purge Monitor®

Measuring Down to 1 ppm!

The latest addition to the Family Range of PurgEye ® Weld Purge Monitors ® is the PurgEye ® 1-500 Site, portable, robust and specifically designed for site conditions.

The PurgEye ® Site reads oxygen levels from 1000 ppm, right down to 1 ppm (accurate to 10 ppm) with a long life sensor and new, ultra sharp OLED screen.

The PurgEye ® Site is mounted in a conveniently sized outer case, which seals it to IP68 standard when the lid is closed.

The Family Range of Weld Purge Monitors® have become the standard Weld Purge instruments of today, recognised and used by companies who need to produce quality welds, where an Oxygen Analzyer is not sufficient for weld purging.

PurgEye ® is a Family Series of Weld Purge Monitors ®.

-

High Purity Equipment

HFT PurgEye® 200 IP65 Rechargeable Weld Purge Monitor®

Accurately measuring down to 10 ppm

Now with an OLED (organic light emitting diode) display, the PurgEye ® 200 Weld Purge Monitor ® gives sharper, brighter and clearer readings for viewing at longer distances than before. The OLED display is mainly symbol based, which means the menus are easily understandable regardless of which languages the user speaks.

Main Features:

• Internal electro-mechanical pump with 1 l/m flow rate.• USB lead included to control PurgeLog™ software.

• IP65 rated.

• Long life, faster response sensor.

• Internal rechargeable battery or mains power operated.

• Battery life up to 10 hours.

• Hand held easy to use instrument.

• Warning alarm levels between 1 and 999 ppm.

• Flow detection for accurate reading of gas samples.

• Outstanding protection against HF interference.

• Large character OLED screen for easy reading.

• Power on / off with standby button for sensor warm up.

• Can be charged by plugging directly into mains power with charging lead or optional charging dock.

-

High Purity Equipment

Argweld® PurgEye® 300 Nano Weld Purge Monitor®

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.

-

High Purity Equipment

Argweld® PurgEye® 300 Plus Small and Lightweight

Purpose-designed Purge Monitor

The Argweld® PurgEye® 300 Nano Weld Purge Monitor® has been specifically designed as a very low cost, basic entry level version of the Argweld® PurgEye® 300 for indicating low oxygen levels in inert gas for weld purging down to 10 ppm.

With a large alpha-numeric display, the Argweld® PurgEye® 300 ‘Nano’ measures very accurately from 1000 ppm down to 10 ppm.

The Argweld® PurgEye® 300 ‘Nano’ uses a unique new low cost long life sensor which has very little maintenance requirement and avoids the disadvantages of monitors with ‘wet cell’ technology that have to be constantly calibrated and have sensors replaced.

Argweld® PurgEye® 300 Nano Weld Purge Monitors® are available for immediate delivery.