Mig Machines

Showing 1–15 of 17 results

-

Mig Machines, Lincoln Mig Welders, MIG Welding

Lincoln Electric Powertec i420 Mig Welder 400v

Price Listed for i420 & LF52 5mtr Aircooled package , subject to vat.

Package includes……LGS360 Mig Gun 4mtr, earth, regulator, calibration, delivery

Priced on application call Dublin or Cork for quotation.

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln Electric Powertec i500 Mig Welder 400v

Price Listed for i500 & LF52 5mtr Aircooled package , subject to vat.

Package includes……LGS360 Mig Gun 4mtr, earth, regulator, calibration, delivery

Priced on application call Dublin or Cork for quotation.

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Electric Speedtec® 180C MultiProcess Inverter Welder

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, FCW, Stick

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible.

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Speedtec® 200C

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, CV Synergic, FCAW, Stick, TIG Lift

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

Input Power

- 115-230/1/50/60

Processes

CV MIG, FCAW, Stick, LIFT TIG

SKU: n/a -

Lincoln Multiprocess Welding, MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln Speedtec® 215C

Top Features

- Multiple Tasks: MIG, FCAW, Stick, TIG Lift – designed for many jobs!

- Excellent welding characteristics with all proccesses

- Smart housing: 15kg spool, helpful shelves, useful in workshop or production workshop

- User Friendly icon control panel, makes set up is easy for experts and beginners

- Power Factor Correction (PFC) gives more power to arc, consume up to 30% less energy, work on 100m extension cable

Input Power

- 115-230/1/50/60

Processes

CV MIG manual, CV MIG synergic, FCAW, STICK, LIFT TIG

SKU: k14146-1 -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 350X (STANDARD MODEL)

A RUGGED MULTI-PROCESS POWER SOURCE FOR MAXIMUM FLEXIBILITY

Out on the construction jobsite or in most fabrication shops, it pays to keep it simple. The Flextec 350X multi-process welder is designed for that kind of environment. These multi-process welders are easy to setup and easy to operate, yet rugged and flexible enough to be used in construction, fabrication, shipbuilding and other heavy-duty applications.

Simple

- Streamlined operator panel minimizes setup time

- Plug in to any 380-600V 3 phase power

- Easy process selection

Reliable

- Built on industry proven design elements of other popular Lincoln Electric welders

- Components designed to run cool for long life in high temperature environments

- Fully encapsulated and environmentally protected electronics

- Engineered for outdoor use and harsh environments (IP23 rated)

Flexible

- Compatible with across-the-arc, analog, digital or CrossLinc™ feeders

- Premium multi-process arc characteristics works with all DC wire, stick and TIG processes

- Choice of models to fit any application and budget

- Lightweight and portable

Product Highlights

- Desert Duty Rated™ for extreme temperatures up to 55°C

- VRD® Voltage Reduction Device reduces Open Circuit Voltage for added safety

- Offered in 4 and 6 pack rack configurations

- Wide 5-425 amperage range

- Capable of Arc Gouging with 3/16 in. (4.8 mm) carbons

CrossLinc™ Technology

- Full functionality without control cables

- Enables remote procedure setting at the feeder to improve weld quality

- Increase arc time with fewer trips to the power source to adjust settings

- Improves safety by reducing jobsite clutter

CROSSLINC™ TECHNOLOGY: SOLVING SITE WELDING ISSUES

Worker safety, weld quality, productivity and equipment reliability come to mind when welding on site or on large structures. In these environments, it is typical for the operator to work closely with a rugged, compact and lightweight wire feeder, connected to a weather-resistant power source hundreds of feet away. Until now, portable wire feeders have been available in two configurations: basic ‘across-the-arc’ models or portable feeders equipped with an added control cable.

‘Across-the-arc’ models are powered by the weld cable. This configuration provides benefits of fewer cables running back to the power source, but voltage control at the point-of-use is

not possible.The addition of a control cable to the system allows the operator to adjust voltage at the point-of-use, but these cables can be costly and add additional complexity to the production environment.

There has to be a better way.

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

SKU: n/a -

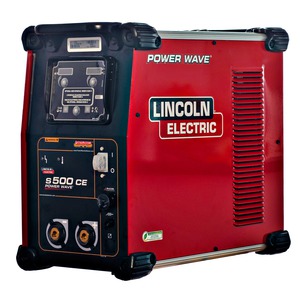

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

SKU: n/a

-

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Electric Speedtec® 180C MultiProcess Inverter Welder

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, FCW, Stick

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible.

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

-

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Speedtec® 200C

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, CV Synergic, FCAW, Stick, TIG Lift

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

Input Power

- 115-230/1/50/60

Processes

CV MIG, FCAW, Stick, LIFT TIG

-

Lincoln Multiprocess Welding, MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln Speedtec® 215C

Top Features

- Multiple Tasks: MIG, FCAW, Stick, TIG Lift – designed for many jobs!

- Excellent welding characteristics with all proccesses

- Smart housing: 15kg spool, helpful shelves, useful in workshop or production workshop

- User Friendly icon control panel, makes set up is easy for experts and beginners

- Power Factor Correction (PFC) gives more power to arc, consume up to 30% less energy, work on 100m extension cable

Input Power

- 115-230/1/50/60

Processes

CV MIG manual, CV MIG synergic, FCAW, STICK, LIFT TIG

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 350X (STANDARD MODEL)

A RUGGED MULTI-PROCESS POWER SOURCE FOR MAXIMUM FLEXIBILITY

Out on the construction jobsite or in most fabrication shops, it pays to keep it simple. The Flextec 350X multi-process welder is designed for that kind of environment. These multi-process welders are easy to setup and easy to operate, yet rugged and flexible enough to be used in construction, fabrication, shipbuilding and other heavy-duty applications.

Simple

- Streamlined operator panel minimizes setup time

- Plug in to any 380-600V 3 phase power

- Easy process selection

Reliable

- Built on industry proven design elements of other popular Lincoln Electric welders

- Components designed to run cool for long life in high temperature environments

- Fully encapsulated and environmentally protected electronics

- Engineered for outdoor use and harsh environments (IP23 rated)

Flexible

- Compatible with across-the-arc, analog, digital or CrossLinc™ feeders

- Premium multi-process arc characteristics works with all DC wire, stick and TIG processes

- Choice of models to fit any application and budget

- Lightweight and portable

Product Highlights

- Desert Duty Rated™ for extreme temperatures up to 55°C

- VRD® Voltage Reduction Device reduces Open Circuit Voltage for added safety

- Offered in 4 and 6 pack rack configurations

- Wide 5-425 amperage range

- Capable of Arc Gouging with 3/16 in. (4.8 mm) carbons

CrossLinc™ Technology

- Full functionality without control cables

- Enables remote procedure setting at the feeder to improve weld quality

- Increase arc time with fewer trips to the power source to adjust settings

- Improves safety by reducing jobsite clutter

CROSSLINC™ TECHNOLOGY: SOLVING SITE WELDING ISSUES

Worker safety, weld quality, productivity and equipment reliability come to mind when welding on site or on large structures. In these environments, it is typical for the operator to work closely with a rugged, compact and lightweight wire feeder, connected to a weather-resistant power source hundreds of feet away. Until now, portable wire feeders have been available in two configurations: basic ‘across-the-arc’ models or portable feeders equipped with an added control cable.

‘Across-the-arc’ models are powered by the weld cable. This configuration provides benefits of fewer cables running back to the power source, but voltage control at the point-of-use is

not possible.The addition of a control cable to the system allows the operator to adjust voltage at the point-of-use, but these cables can be costly and add additional complexity to the production environment.

There has to be a better way.

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Electric Speedtec® 180C MultiProcess Inverter Welder

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, FCW, Stick

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible.

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

-

MIG Welding, Mig Machines, Lincoln Mig Welders, Lincoln Multiprocess Welding

Lincoln Speedtec® 200C

Top Features

- Compact and Robust, Innovative, Portable and Lightweight, Anyplace, Anywhere

- Multiple Tasks: CV MIG, CV Synergic, FCAW, Stick, TIG Lift

- Power Factor Correction (PFC). More Welding Power, Energy and Cost savings, Generator Compatible

- User Friendly Operation: Icon control panel (Speedtec® 180C) Icon control colour TFT Interface screen (Speedtec® 200C).

- Superior Arc Performance. CV MIG: Infinitely Variable Control of voltage, Wire Feed Seed and Inductance, Stick: Hot Start and Arc Force Control, TIG: Lift TIG avoids Tungsten contamination.

Input Power

- 115-230/1/50/60

Processes

CV MIG, FCAW, Stick, LIFT TIG

-

Lincoln Multiprocess Welding, MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln Speedtec® 215C

Top Features

- Multiple Tasks: MIG, FCAW, Stick, TIG Lift – designed for many jobs!

- Excellent welding characteristics with all proccesses

- Smart housing: 15kg spool, helpful shelves, useful in workshop or production workshop

- User Friendly icon control panel, makes set up is easy for experts and beginners

- Power Factor Correction (PFC) gives more power to arc, consume up to 30% less energy, work on 100m extension cable

Input Power

- 115-230/1/50/60

Processes

CV MIG manual, CV MIG synergic, FCAW, STICK, LIFT TIG

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 350X (STANDARD MODEL)

A RUGGED MULTI-PROCESS POWER SOURCE FOR MAXIMUM FLEXIBILITY

Out on the construction jobsite or in most fabrication shops, it pays to keep it simple. The Flextec 350X multi-process welder is designed for that kind of environment. These multi-process welders are easy to setup and easy to operate, yet rugged and flexible enough to be used in construction, fabrication, shipbuilding and other heavy-duty applications.

Simple

- Streamlined operator panel minimizes setup time

- Plug in to any 380-600V 3 phase power

- Easy process selection

Reliable

- Built on industry proven design elements of other popular Lincoln Electric welders

- Components designed to run cool for long life in high temperature environments

- Fully encapsulated and environmentally protected electronics

- Engineered for outdoor use and harsh environments (IP23 rated)

Flexible

- Compatible with across-the-arc, analog, digital or CrossLinc™ feeders

- Premium multi-process arc characteristics works with all DC wire, stick and TIG processes

- Choice of models to fit any application and budget

- Lightweight and portable

Product Highlights

- Desert Duty Rated™ for extreme temperatures up to 55°C

- VRD® Voltage Reduction Device reduces Open Circuit Voltage for added safety

- Offered in 4 and 6 pack rack configurations

- Wide 5-425 amperage range

- Capable of Arc Gouging with 3/16 in. (4.8 mm) carbons

CrossLinc™ Technology

- Full functionality without control cables

- Enables remote procedure setting at the feeder to improve weld quality

- Increase arc time with fewer trips to the power source to adjust settings

- Improves safety by reducing jobsite clutter

CROSSLINC™ TECHNOLOGY: SOLVING SITE WELDING ISSUES

Worker safety, weld quality, productivity and equipment reliability come to mind when welding on site or on large structures. In these environments, it is typical for the operator to work closely with a rugged, compact and lightweight wire feeder, connected to a weather-resistant power source hundreds of feet away. Until now, portable wire feeders have been available in two configurations: basic ‘across-the-arc’ models or portable feeders equipped with an added control cable.

‘Across-the-arc’ models are powered by the weld cable. This configuration provides benefits of fewer cables running back to the power source, but voltage control at the point-of-use is

not possible.The addition of a control cable to the system allows the operator to adjust voltage at the point-of-use, but these cables can be costly and add additional complexity to the production environment.

There has to be a better way.

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input