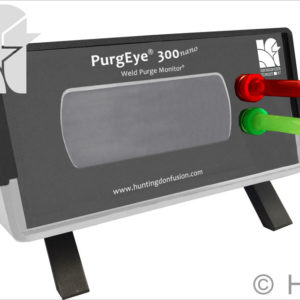

Argweld® PurgEye® 100 Hand Held IP65 Weld Purge Monitor®

Argweld® PurgEye® 100 IP65 has additional features that place this Weld Purge Monitor® way ahead in the field of Weld Purge Monitoring.

Huntingdon Fusion Techniques HFT® is the first company to have developed a Weld Purge Monitor®. The Company has continued to innovate year by year bringing to the market place a complete family range of weld purge monitoring instruments for other materials including duplex, nickel and cobalt steels, titanium, zirconium and other reactive alloys.

Joining the other existing models in the range, the Argweld® PurgEye® 100 IP65 makes Huntingdon Fusion Techniques HFT® the only Company to have a complete ‘family’ of Weld Purge Monitors® s for all applications and to suit every budget.

This exciting new PurgEye® 100 IP65 Weld Purge Monitor® replaces our out of date and obsolete Argweld® Mark V (MKV) Weld Purge Monitor® which used old technology in comparison with this latest revoluntary model.

Hi-tech developments on the Argweld® PurgEye® 100 IP65 Weld Purge Monitor® include:

• IP65 dustproof and waterproof accredited

• Vacuum brazed leak tight probe assembly

• Push button “Auto Calibration” feature

• Low battery indicator and low sensor indicator

• Enlarged screen and large size digits

• Tripod mount (for fixed and gorilla tripods)

• Automatic sleep mode when not in use

• Leak tight quick connect/disconnect fittings for gas purge tubing

• Protective rubber cover (optional)

• More robust carry/presentation storage case

The innovative Push Button Auto Calibration facility on the front of the instrument allows the user to calibrate at atmospheric level and again at the lowest oxygen reading for increased accuracy.

With tungsten inert gas welding (gas tungsten arc welding) of important joints in stainless steels and other reactive metals, before commencing the weld, it is essential to know that the oxygen content in the welding volume has been reduced to a satisfactorily low level.

Argweld® PurgEye® 100 IP65 Weld Purge Monitors® s will carry out this task for you indicating oxygen levels down to 100 ppm.

Internationally recognised as the premier day to day Weld Purge Monitor®, the PurgEye® 100 IP65 has become the standard oxygen measuring instrument in the industry.

This very affordable hand held meter is a ‘must’ for every construction site and pipework fabrication facility around the world.

Brand

Huntingdon Fusion

Based on 0 reviews

Be the first to review “Argweld® PurgEye® 100 Hand Held IP65 Weld Purge Monitor®”

You must be logged in to post a review.

There are no reviews yet.