MIG Welding

Showing 46–53 of 53 results

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

SKU: n/a -

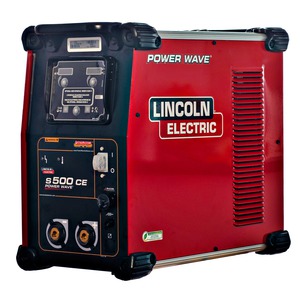

Lincoln Mig Welders, MIG Welding, Mig Machines

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln STT® MODULE

Top Features

- Add STT® (Surface Tension Transfer®) process capability to any compatible Power Wave® S-Series power source to gain outstanding puddle control for critical metal or pipe root pass welding.

- Exceptional Arc Control – Outstanding burnthrough control on thin metal or critical pipe welding

- UltimArc® – in synergic STT® modes

- Modular Design

- Compact Footprint

Processes

MIG-STT

Output

Input

SKU: n/a -

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 650X

Top Features

- Use with a wide range of available 3 phase input power

- Easy one-knob process selection

- Tough IP23 enclosure rating

- Ideal for large diameter wire or stick welding on thick materials

- Full functionality without control cables

Input Power

- 380/460/575/3/50/60

Processes

Stick, TIG, MIG, Flux-Cored, Submerged Arc, Gouging

Output

Input

SKU: n/a -

Mig Wire, Mig Wires

Lincoln Electric SUPRAMIG ULTRA® Mig Wire

AWS: ER70S-6

Top Features

- Solid wire with increased manganese for semi-automatic welding and robotic applications

- Excellent feedability and very consistent welding performance

- Tight and stable arc with extremely low spatter

- Available in 16kg coils and Accutrak® drums 250/500/1000kg

Typical Applications

- Transportation

- Pipeline

- Energy

Welding Positions ALL

Shielding Gas

- M21: Mixed gas Ar+ >15 to 25% CO2

- C1 : Active gas 100% CO2

SKU: n/a

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

Lincoln Mig Welders, MIG Welding, Mig Machines

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln STT® MODULE

Top Features

- Add STT® (Surface Tension Transfer®) process capability to any compatible Power Wave® S-Series power source to gain outstanding puddle control for critical metal or pipe root pass welding.

- Exceptional Arc Control – Outstanding burnthrough control on thin metal or critical pipe welding

- UltimArc® – in synergic STT® modes

- Modular Design

- Compact Footprint

Processes

MIG-STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 650X

Top Features

- Use with a wide range of available 3 phase input power

- Easy one-knob process selection

- Tough IP23 enclosure rating

- Ideal for large diameter wire or stick welding on thick materials

- Full functionality without control cables

Input Power

- 380/460/575/3/50/60

Processes

Stick, TIG, MIG, Flux-Cored, Submerged Arc, Gouging

Output

Input

-

Mig Wire, Mig Wires

Lincoln Electric SUPRAMIG ULTRA® Mig Wire

AWS: ER70S-6

Top Features

- Solid wire with increased manganese for semi-automatic welding and robotic applications

- Excellent feedability and very consistent welding performance

- Tight and stable arc with extremely low spatter

- Available in 16kg coils and Accutrak® drums 250/500/1000kg

Typical Applications

- Transportation

- Pipeline

- Energy

Welding Positions ALL

Shielding Gas

- M21: Mixed gas Ar+ >15 to 25% CO2

- C1 : Active gas 100% CO2

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln INVERTEC® STT® II

Top Features

- Controlled penetration and outstanding heat input control—Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

- Reduced spatter and fumes—Current is controlled to achieve optimal metal transfer.

- Various shielding gases—blends of Argon including Helium or 100% CO2 with larger diameter wires.

- Good bead control and faster travel speeds—Can replace TIG in many applications.

- Background and Tailout Current—accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

Input Power

- 200/220/380/400/440/3/50-60

Processes

MIG, STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln POWER WAVE® S350

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT®and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

Lincoln Mig Welders, MIG Welding, Mig Machines

Lincoln POWER WAVE® S500

Top Features

- Unlimited set of Standard, Pulse and advanced Arc processes, with optional the addition of STT® and Rapid X, more than 100 weld modes inside Stick and TIG DC.

- Free software updates, to upgrade each Power Wave® with the latest arc programs at any time. NO difference between the upgraded machine and a new one.

- Ethernet as standard : Free software, like Power Wave Manager and Check Point or Production Monitoring for a single machine or multiple in a network.

Input Power

- 230/400/3/50-60

Processes

Stick, DC TIG, Pulsed DC TIG, MIG, Pulsed MIG, Flux-Cored

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln STT® MODULE

Top Features

- Add STT® (Surface Tension Transfer®) process capability to any compatible Power Wave® S-Series power source to gain outstanding puddle control for critical metal or pipe root pass welding.

- Exceptional Arc Control – Outstanding burnthrough control on thin metal or critical pipe welding

- UltimArc® – in synergic STT® modes

- Modular Design

- Compact Footprint

Processes

MIG-STT

Output

Input

-

MIG Welding, Mig Machines, Lincoln Mig Welders

Lincoln FLEXTEC® 650X

Top Features

- Use with a wide range of available 3 phase input power

- Easy one-knob process selection

- Tough IP23 enclosure rating

- Ideal for large diameter wire or stick welding on thick materials

- Full functionality without control cables

Input Power

- 380/460/575/3/50/60

Processes

Stick, TIG, MIG, Flux-Cored, Submerged Arc, Gouging

Output

Input

-

Mig Wire, Mig Wires

Lincoln Electric SUPRAMIG ULTRA® Mig Wire

AWS: ER70S-6

Top Features

- Solid wire with increased manganese for semi-automatic welding and robotic applications

- Excellent feedability and very consistent welding performance

- Tight and stable arc with extremely low spatter

- Available in 16kg coils and Accutrak® drums 250/500/1000kg

Typical Applications

- Transportation

- Pipeline

- Energy

Welding Positions ALL

Shielding Gas

- M21: Mixed gas Ar+ >15 to 25% CO2

- C1 : Active gas 100% CO2