Pipe Fit-Up Tools

Showing 31–42 of 42 results

-

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MA Battery Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– New brushless motor 18V

– Accurate manual advance, gratuated vernier scale

– Light and compact (5.5 kg)

– Come with two 18V Li-Power, 5.2 Ah batteries and a fast battery charger

– 2 mechanical speeds + electric speed variator

– Clamping shells : stainless steel jaws with spring (priced separately per diameter)SKU: n/a -

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MS Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– Mains motor 1100 W Metabo Drive

– 220-240 V ~50/60Hz or 120 V ~ 50/60Hz

– Accurate manual advance, graduated vernier scale

– Light and compact (5.5 kg)

– Two speed gearbox with variable speed drive

– High quality speed controller

– Clamping shells : stainless steel jaws with spring (priced separately per Diameter)SKU: n/a -

High Purity Equipment, Tube Cutting & Facing, Axxair Orbital Welding

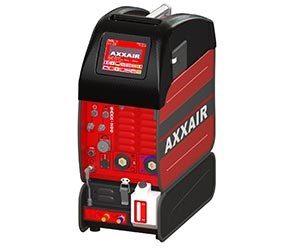

Axxair SAXX 200 Orbital Inverter Power Supply

- Now only available on the Metron Hire Fleet, replaced by SAXX-201

- SAXX-200 Orbital TIG Power Source for Orbital Fusion Welding Heads

- 7.5″ Color Touch Screen Interface

- 110V to 230V

This Axxair Orbital Inverter power supply features a 7.5″ color touch screen and auto-calculated program settings based on diameter, thickness, configuration and material.

-

- 200A maximum current, 120A 100% (230V)

- 140A maximum current, 100A 100% (110V)

- Auto line, 110V to 230V +/- 15% (mono – 50/60hz)

- 7.5″ color touch screen interface

- Auto calculation for program setting through diameter, thickness, configuration and material

- Programs from 1 to 20 levels

- Step modes advance speed-wire pulse

- Dual gas control: purge gas (through purge time, as well as electrode gas, through pre-gas, or ppm

levels)

- Compatible with oxygen measuring systems

- USB program storage: 200 programs per stick

SKU: n/a -

Pipe Bevelling Machines, Pipe Fitters Tools, HIRE FLEET, Pipe Tool Hire

G.B.C. BOILER K Pipe Prepping Machine 28mm- 76mm

GBC Boiler K Electric 110vPortable Pipe Bevelling MachineRange ID 28mm – 76mm (1.10”-2.99”)E;ectric Motor as Standard. Battery & Pneumatic Drive avaialble alsoThree point ID Clamping2Tool Holders (Allowing for Bevel and Land in single Process)OD Bevelling, Pipe Facing, Counterboring.Suitable for Carbon, Stainless, Duplex, Inconnell and other alloys.Optional Reducer Shaft to bring the ID Range down to 20mm – 30mm RangeBOILER K : versatile, robust and powerful model. Widely used is mechanical installation processes, boiler maintenance in power station shut-down and new boiler vessels manufacturing.SKU: n/a

GBC Boiler K Electric 110vPortable Pipe Bevelling MachineRange ID 28mm – 76mm (1.10”-2.99”)E;ectric Motor as Standard. Battery & Pneumatic Drive avaialble alsoThree point ID Clamping2Tool Holders (Allowing for Bevel and Land in single Process)OD Bevelling, Pipe Facing, Counterboring.Suitable for Carbon, Stainless, Duplex, Inconnell and other alloys.Optional Reducer Shaft to bring the ID Range down to 20mm – 30mm RangeBOILER K : versatile, robust and powerful model. Widely used is mechanical installation processes, boiler maintenance in power station shut-down and new boiler vessels manufacturing.SKU: n/a -

Pipe Bevelling Machines

G.B.C. BOILER STD 1/4

Portable pipe beveling machines

Portable pipe beveling machinesBOILER 1/4

RANGE ØI 23-108 MM (0.90”-4.25”)Pipe bevelling machine BOILER 1-4, in pneumatic version, is indicated for prefabrication for its reduced weight and easy handling.Electric version of this beveling machine is also available, or a conversion kit to easily change pneumatic to electric.

It is also equipped with auto locking device for time saving in repetitive work.

RANGE:

23 – 108 mm i/d.FUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric.NOTE:

The weight/power ratio makes it for maintenance in power station shut-downs.SKU: n/a -

Pipe Bevelling Machines

G.B.C. HYPERMAXI 20_36

New pipe bevelling machine with a wide inside locking range

New pipe bevelling machine with a wide inside locking rangeHYPERMAXI 20_36

RANGE 508 – 937 MM (20” – 36”)New pipe bevelling machine with a wide inside locking range from 20” to 36”

Its versatility makes this machine suitable for a wide selection of applications in several fields.Its strength is the ability of removing material in large quantity, achievable both with the HSS and insert type, interchangeable tooling with Supermaxi 7_24.

- Innovative locking system;

- Portable Machine;

- Flexibility, versatility in regard to the application fields;

- Available in pneumatic and hydraulic version;

- Tooling interchangeable with those of the Supermaxi 7_24;

- High rate removal capability.

SKU: n/a -

Pipe Bevelling Machines

G.B.C. MINI K

Portable pipe bevelling machineRANGE ØI 20-42 MM (0,78”-1,78”)Pipe beveler MINI K, with 60mm body and cutter head, is perfect for jobs in restricted access areas.

Portable pipe bevelling machineRANGE ØI 20-42 MM (0,78”-1,78”)Pipe beveler MINI K, with 60mm body and cutter head, is perfect for jobs in restricted access areas.This pipe beveler is available in pneumatic version, as well as in electric version, with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

20 – 42 mm i/d (optional from 12,5 mm i/d).FUNCTIONS:

Pipe beveler ideal for bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric/batteryNOTE:

The MINI K machine is a lightweight and powerful pipe beveler, the best in power station shut-down work thanks to its reduced size, easy handling and quick set up.SKU: n/a -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T4

Portable pipe bevelling machine

Portable pipe bevelling machineSUPERBOILER T4

RANGE ØI 39-104 MM (1.53”-4.09”)Pipe beveler SUPERBOILER T4 is an extremely powerful model, designed to handle tough heavy wall tubes.SUPERBOILER T4 is available in pneumatic version, as well as in electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

39 – 104 mm i/dFUNCTIONS:

SUPERBOILER for beveling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

Generous torque allows single pass bevel on heavy wall thickness.SKU: n/a -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T5

Portable pipe bevelling machine

Portable pipe bevelling machineSUPERBOILER T5

RANGE ØI 49-203 MM (1.92”-7.99”)Pipe bevelling machine SUPERBOILER T5 in pneumatic version with superior torque is reliable even in the toughest heavy duty working conditions.

This pipe bevelling machine is available in pneumatic or electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

49 – 207 mm i/dFUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

This pipe bevelling machine is a powerful model with wide range able to produce accurate weld preps on any schedule and material of pipe. Options includes flange facing module.SKU: n/a -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 4-16

Pipe beveler

Pipe bevelerSUPERMAXI 4-16

RANGE Ø 94,5– 318,5MM (3,7”-12,5”)The unit is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.

RANGE:

Working range from 3,7” to 12,5” (94,5-318,5mm) in standard configuration and up to 16,45” (418mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts.SKU: n/a -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 7-24

Pipe beveler

Pipe bevelerSUPERMAXI 7-24

RANGE Ø 180-504 MM (7,08” – 19,84”)This pipe beveler is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.RANGE:

Working range from 7” to 20” (180-504mm) in standard configuration and up to 24” (590mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts.SKU: n/a -

Tube Cutting & Facing, Tube Severing

MODEL 576AC SEVERMASTER

Tube Severing Machine

The Model 576AC SEVERMASTER™ severs 2.0” to 6.63″ (50.8 to 168.4mm) diameter tubes and thin wall pipe. This machine enhances productivity by incorporation of the auto-cycle tool model and quick lock collet closure. A cam cycle tool bit feed mechanism, with adjustable depth of feed from .001” to .005” (.02 to .13mm), automatically returns the tool bit to the home position ready to start the next cut. The feed increment per revolution is adjustable to optimize the cutting speed relative to the material. The tool module also allows setting the start and finish cut positions to minimize the cycle time. A variable speed motor provides further cutting speed control for increased tool bit life and ID burr reduction. The quick lock mechanism actuates the collet with a single lever stroke for simple collet changes. The Model 576AC has a collet clamping length of 3.00” (76.2mm).

Tool bit options are available to minimize the burr on the mounting side or the drop-off side of the sever line and in different edge widths to match the tube wall thickness. The tool also incorporates mounting features to allow use of an SQM-2AC Tube Squaring Module for optimum burr free ends.

SKU: n/a

-

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MA Battery Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– New brushless motor 18V

– Accurate manual advance, gratuated vernier scale

– Light and compact (5.5 kg)

– Come with two 18V Li-Power, 5.2 Ah batteries and a fast battery charger

– 2 mechanical speeds + electric speed variator

– Clamping shells : stainless steel jaws with spring (priced separately per diameter) -

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MS Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– Mains motor 1100 W Metabo Drive

– 220-240 V ~50/60Hz or 120 V ~ 50/60Hz

– Accurate manual advance, graduated vernier scale

– Light and compact (5.5 kg)

– Two speed gearbox with variable speed drive

– High quality speed controller

– Clamping shells : stainless steel jaws with spring (priced separately per Diameter) -

High Purity Equipment, Tube Cutting & Facing, Axxair Orbital Welding

Axxair SAXX 200 Orbital Inverter Power Supply

- Now only available on the Metron Hire Fleet, replaced by SAXX-201

- SAXX-200 Orbital TIG Power Source for Orbital Fusion Welding Heads

- 7.5″ Color Touch Screen Interface

- 110V to 230V

This Axxair Orbital Inverter power supply features a 7.5″ color touch screen and auto-calculated program settings based on diameter, thickness, configuration and material.

-

- 200A maximum current, 120A 100% (230V)

- 140A maximum current, 100A 100% (110V)

- Auto line, 110V to 230V +/- 15% (mono – 50/60hz)

- 7.5″ color touch screen interface

- Auto calculation for program setting through diameter, thickness, configuration and material

- Programs from 1 to 20 levels

- Step modes advance speed-wire pulse

- Dual gas control: purge gas (through purge time, as well as electrode gas, through pre-gas, or ppm

levels)

- Compatible with oxygen measuring systems

- USB program storage: 200 programs per stick

-

Pipe Bevelling Machines, Pipe Fitters Tools, HIRE FLEET, Pipe Tool Hire

G.B.C. BOILER K Pipe Prepping Machine 28mm- 76mm

GBC Boiler K Electric 110vPortable Pipe Bevelling MachineRange ID 28mm – 76mm (1.10”-2.99”)E;ectric Motor as Standard. Battery & Pneumatic Drive avaialble alsoThree point ID Clamping2Tool Holders (Allowing for Bevel and Land in single Process)OD Bevelling, Pipe Facing, Counterboring.Suitable for Carbon, Stainless, Duplex, Inconnell and other alloys.Optional Reducer Shaft to bring the ID Range down to 20mm – 30mm RangeBOILER K : versatile, robust and powerful model. Widely used is mechanical installation processes, boiler maintenance in power station shut-down and new boiler vessels manufacturing. -

Pipe Bevelling Machines

G.B.C. BOILER STD 1/4

Portable pipe beveling machinesBOILER 1/4

RANGE ØI 23-108 MM (0.90”-4.25”)Pipe bevelling machine BOILER 1-4, in pneumatic version, is indicated for prefabrication for its reduced weight and easy handling.Electric version of this beveling machine is also available, or a conversion kit to easily change pneumatic to electric.

It is also equipped with auto locking device for time saving in repetitive work.

RANGE:

23 – 108 mm i/d.FUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric.NOTE:

The weight/power ratio makes it for maintenance in power station shut-downs. -

Pipe Bevelling Machines

G.B.C. HYPERMAXI 20_36

New pipe bevelling machine with a wide inside locking rangeHYPERMAXI 20_36

RANGE 508 – 937 MM (20” – 36”)New pipe bevelling machine with a wide inside locking range from 20” to 36”

Its versatility makes this machine suitable for a wide selection of applications in several fields.Its strength is the ability of removing material in large quantity, achievable both with the HSS and insert type, interchangeable tooling with Supermaxi 7_24.

- Innovative locking system;

- Portable Machine;

- Flexibility, versatility in regard to the application fields;

- Available in pneumatic and hydraulic version;

- Tooling interchangeable with those of the Supermaxi 7_24;

- High rate removal capability.

-

Pipe Bevelling Machines

G.B.C. MINI K

Portable pipe bevelling machineRANGE ØI 20-42 MM (0,78”-1,78”)Pipe beveler MINI K, with 60mm body and cutter head, is perfect for jobs in restricted access areas.This pipe beveler is available in pneumatic version, as well as in electric version, with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

20 – 42 mm i/d (optional from 12,5 mm i/d).FUNCTIONS:

Pipe beveler ideal for bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric/batteryNOTE:

The MINI K machine is a lightweight and powerful pipe beveler, the best in power station shut-down work thanks to its reduced size, easy handling and quick set up. -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T4

Portable pipe bevelling machineSUPERBOILER T4

RANGE ØI 39-104 MM (1.53”-4.09”)Pipe beveler SUPERBOILER T4 is an extremely powerful model, designed to handle tough heavy wall tubes.SUPERBOILER T4 is available in pneumatic version, as well as in electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

39 – 104 mm i/dFUNCTIONS:

SUPERBOILER for beveling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

Generous torque allows single pass bevel on heavy wall thickness. -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T5

Portable pipe bevelling machineSUPERBOILER T5

RANGE ØI 49-203 MM (1.92”-7.99”)Pipe bevelling machine SUPERBOILER T5 in pneumatic version with superior torque is reliable even in the toughest heavy duty working conditions.

This pipe bevelling machine is available in pneumatic or electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

49 – 207 mm i/dFUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

This pipe bevelling machine is a powerful model with wide range able to produce accurate weld preps on any schedule and material of pipe. Options includes flange facing module. -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 4-16

Pipe bevelerSUPERMAXI 4-16

RANGE Ø 94,5– 318,5MM (3,7”-12,5”)The unit is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.

RANGE:

Working range from 3,7” to 12,5” (94,5-318,5mm) in standard configuration and up to 16,45” (418mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts. -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 7-24

Pipe bevelerSUPERMAXI 7-24

RANGE Ø 180-504 MM (7,08” – 19,84”)This pipe beveler is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.RANGE:

Working range from 7” to 20” (180-504mm) in standard configuration and up to 24” (590mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts. -

Tube Cutting & Facing, Tube Severing

MODEL 576AC SEVERMASTER

Tube Severing Machine

The Model 576AC SEVERMASTER™ severs 2.0” to 6.63″ (50.8 to 168.4mm) diameter tubes and thin wall pipe. This machine enhances productivity by incorporation of the auto-cycle tool model and quick lock collet closure. A cam cycle tool bit feed mechanism, with adjustable depth of feed from .001” to .005” (.02 to .13mm), automatically returns the tool bit to the home position ready to start the next cut. The feed increment per revolution is adjustable to optimize the cutting speed relative to the material. The tool module also allows setting the start and finish cut positions to minimize the cycle time. A variable speed motor provides further cutting speed control for increased tool bit life and ID burr reduction. The quick lock mechanism actuates the collet with a single lever stroke for simple collet changes. The Model 576AC has a collet clamping length of 3.00” (76.2mm).

Tool bit options are available to minimize the burr on the mounting side or the drop-off side of the sever line and in different edge widths to match the tube wall thickness. The tool also incorporates mounting features to allow use of an SQM-2AC Tube Squaring Module for optimum burr free ends.

-

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MA Battery Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– New brushless motor 18V

– Accurate manual advance, gratuated vernier scale

– Light and compact (5.5 kg)

– Come with two 18V Li-Power, 5.2 Ah batteries and a fast battery charger

– 2 mechanical speeds + electric speed variator

– Clamping shells : stainless steel jaws with spring (priced separately per diameter) -

Pipe Fit-Up Tools, Tube Cutting & Facing

Axxair DC65-MS Tube Facing Machine

Technical characteristics

– Burr-free tube squaring machine

– Mains motor 1100 W Metabo Drive

– 220-240 V ~50/60Hz or 120 V ~ 50/60Hz

– Accurate manual advance, graduated vernier scale

– Light and compact (5.5 kg)

– Two speed gearbox with variable speed drive

– High quality speed controller

– Clamping shells : stainless steel jaws with spring (priced separately per Diameter) -

High Purity Equipment, Tube Cutting & Facing, Axxair Orbital Welding

Axxair SAXX 200 Orbital Inverter Power Supply

- Now only available on the Metron Hire Fleet, replaced by SAXX-201

- SAXX-200 Orbital TIG Power Source for Orbital Fusion Welding Heads

- 7.5″ Color Touch Screen Interface

- 110V to 230V

This Axxair Orbital Inverter power supply features a 7.5″ color touch screen and auto-calculated program settings based on diameter, thickness, configuration and material.

-

- 200A maximum current, 120A 100% (230V)

- 140A maximum current, 100A 100% (110V)

- Auto line, 110V to 230V +/- 15% (mono – 50/60hz)

- 7.5″ color touch screen interface

- Auto calculation for program setting through diameter, thickness, configuration and material

- Programs from 1 to 20 levels

- Step modes advance speed-wire pulse

- Dual gas control: purge gas (through purge time, as well as electrode gas, through pre-gas, or ppm

levels)

- Compatible with oxygen measuring systems

- USB program storage: 200 programs per stick

-

Pipe Bevelling Machines, Pipe Fitters Tools, HIRE FLEET, Pipe Tool Hire

G.B.C. BOILER K Pipe Prepping Machine 28mm- 76mm

GBC Boiler K Electric 110vPortable Pipe Bevelling MachineRange ID 28mm – 76mm (1.10”-2.99”)E;ectric Motor as Standard. Battery & Pneumatic Drive avaialble alsoThree point ID Clamping2Tool Holders (Allowing for Bevel and Land in single Process)OD Bevelling, Pipe Facing, Counterboring.Suitable for Carbon, Stainless, Duplex, Inconnell and other alloys.Optional Reducer Shaft to bring the ID Range down to 20mm – 30mm RangeBOILER K : versatile, robust and powerful model. Widely used is mechanical installation processes, boiler maintenance in power station shut-down and new boiler vessels manufacturing. -

Pipe Bevelling Machines

G.B.C. BOILER STD 1/4

Portable pipe beveling machinesBOILER 1/4

RANGE ØI 23-108 MM (0.90”-4.25”)Pipe bevelling machine BOILER 1-4, in pneumatic version, is indicated for prefabrication for its reduced weight and easy handling.Electric version of this beveling machine is also available, or a conversion kit to easily change pneumatic to electric.

It is also equipped with auto locking device for time saving in repetitive work.

RANGE:

23 – 108 mm i/d.FUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric.NOTE:

The weight/power ratio makes it for maintenance in power station shut-downs. -

Pipe Bevelling Machines

G.B.C. HYPERMAXI 20_36

New pipe bevelling machine with a wide inside locking rangeHYPERMAXI 20_36

RANGE 508 – 937 MM (20” – 36”)New pipe bevelling machine with a wide inside locking range from 20” to 36”

Its versatility makes this machine suitable for a wide selection of applications in several fields.Its strength is the ability of removing material in large quantity, achievable both with the HSS and insert type, interchangeable tooling with Supermaxi 7_24.

- Innovative locking system;

- Portable Machine;

- Flexibility, versatility in regard to the application fields;

- Available in pneumatic and hydraulic version;

- Tooling interchangeable with those of the Supermaxi 7_24;

- High rate removal capability.

-

Pipe Bevelling Machines

G.B.C. MINI K

Portable pipe bevelling machineRANGE ØI 20-42 MM (0,78”-1,78”)Pipe beveler MINI K, with 60mm body and cutter head, is perfect for jobs in restricted access areas.This pipe beveler is available in pneumatic version, as well as in electric version, with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

20 – 42 mm i/d (optional from 12,5 mm i/d).FUNCTIONS:

Pipe beveler ideal for bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electric/batteryNOTE:

The MINI K machine is a lightweight and powerful pipe beveler, the best in power station shut-down work thanks to its reduced size, easy handling and quick set up. -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T4

Portable pipe bevelling machineSUPERBOILER T4

RANGE ØI 39-104 MM (1.53”-4.09”)Pipe beveler SUPERBOILER T4 is an extremely powerful model, designed to handle tough heavy wall tubes.SUPERBOILER T4 is available in pneumatic version, as well as in electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

39 – 104 mm i/dFUNCTIONS:

SUPERBOILER for beveling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

Generous torque allows single pass bevel on heavy wall thickness. -

Pipe Bevelling Machines

G.B.C. SUPERBOILER T5

Portable pipe bevelling machineSUPERBOILER T5

RANGE ØI 49-203 MM (1.92”-7.99”)Pipe bevelling machine SUPERBOILER T5 in pneumatic version with superior torque is reliable even in the toughest heavy duty working conditions.

This pipe bevelling machine is available in pneumatic or electric version, or with a conversion kit to easily change pneumatic to electric.

Auto locking device available for time saving in repetitive work.

RANGE:

49 – 207 mm i/dFUNCTIONS:

Bevelling, facing, counterboring.MATERIALS:

Any kind of steel.POWER:

Pneumatic/electricNOTE:

This pipe bevelling machine is a powerful model with wide range able to produce accurate weld preps on any schedule and material of pipe. Options includes flange facing module. -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 4-16

Pipe bevelerSUPERMAXI 4-16

RANGE Ø 94,5– 318,5MM (3,7”-12,5”)The unit is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.

RANGE:

Working range from 3,7” to 12,5” (94,5-318,5mm) in standard configuration and up to 16,45” (418mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts. -

Pipe Bevelling Machines

G.B.C. SUPERMAXI 7-24

Pipe bevelerSUPERMAXI 7-24

RANGE Ø 180-504 MM (7,08” – 19,84”)This pipe beveler is designed for piping industries and welding workshops for processing pipelines, boilers and fittings.

New generation machine equipped with an innovative 6 points of contact locking system able to grant stability and absence of vibrations during the operations.RANGE:

Working range from 7” to 20” (180-504mm) in standard configuration and up to 24” (590mm) with the optional extension kit.FUNCTIONS:

Milling processes, external and internal tapering, external and internal beveling of pipesMATERIALS:

Steel and special metallic alloysNOTE:

The installation and centering are extremely easy, precise and functional.The uniformity of every single step is granted by a new feeding system and by new motorizations which deliver a constant radial speed for perfect and uniform bevels.

The new machine layout is designed so that the chips of the previous pass will not affect the following passes.

The new mandrel has been designed to be used with standard solid body tools and with wedge locking tools with interchangeable inserts. -

Tube Cutting & Facing, Tube Severing

MODEL 576AC SEVERMASTER

Tube Severing Machine

The Model 576AC SEVERMASTER™ severs 2.0” to 6.63″ (50.8 to 168.4mm) diameter tubes and thin wall pipe. This machine enhances productivity by incorporation of the auto-cycle tool model and quick lock collet closure. A cam cycle tool bit feed mechanism, with adjustable depth of feed from .001” to .005” (.02 to .13mm), automatically returns the tool bit to the home position ready to start the next cut. The feed increment per revolution is adjustable to optimize the cutting speed relative to the material. The tool module also allows setting the start and finish cut positions to minimize the cycle time. A variable speed motor provides further cutting speed control for increased tool bit life and ID burr reduction. The quick lock mechanism actuates the collet with a single lever stroke for simple collet changes. The Model 576AC has a collet clamping length of 3.00” (76.2mm).

Tool bit options are available to minimize the burr on the mounting side or the drop-off side of the sever line and in different edge widths to match the tube wall thickness. The tool also incorporates mounting features to allow use of an SQM-2AC Tube Squaring Module for optimum burr free ends.